Unstoppable by Design.

In 2022, we reinvented the bump stop. Designed for a bottomless, progressive ride feel, with unmatched compression damping and control for a smoother ride.

We built the first truly dynamic bump stop. Our 3D-printed bump stop uses tailored internal air passages to achieve efficient compression damping. As they compress, air resistance through the ports dissipates energy, enhancing impact absorption and vehicle stability. This customizable approach allows for precise performance tuning, offering optimized control across all driving conditions.

Why Switch to Perry Parts?

We leverage the benefits of our modern 3D printing to bring our products to the next level.

DESIGNED

To fit your vehicle perfectly, with an incredibly easy install.

Every Perry Parts product is designed specifically for your vehicle’s exact make and model, not a one-size-fits-all solution. That means you get a flawless, factory-like fit that installs with ease—no cutting, drilling, or complicated modifications required.

TUNED

On a suspension dyno to offer unmatched performance, specifically tailored to your ride.

Because of our infinitely tunable process, we adjust each and every performance characteristic to be perfectly suited for your vehicle. You wouldn't run the same springs on a Tacoma versus a Land Cruiser - so why would you run the same bump stops? We tailor everything we sell to your vehicle.

ENGINEERED

To survive over 100,000 cycles, delivering performance for the long haul.

Engineered with Adaptive Compression Damping and a Variable-Density Progressive Architecture, our bump stops deliver some of the best bottom-out protection available. The progressive design absorbs harsh impacts on the trail while maintaining a soft, comfortable feel for everyday driving.

MANUFACTURED

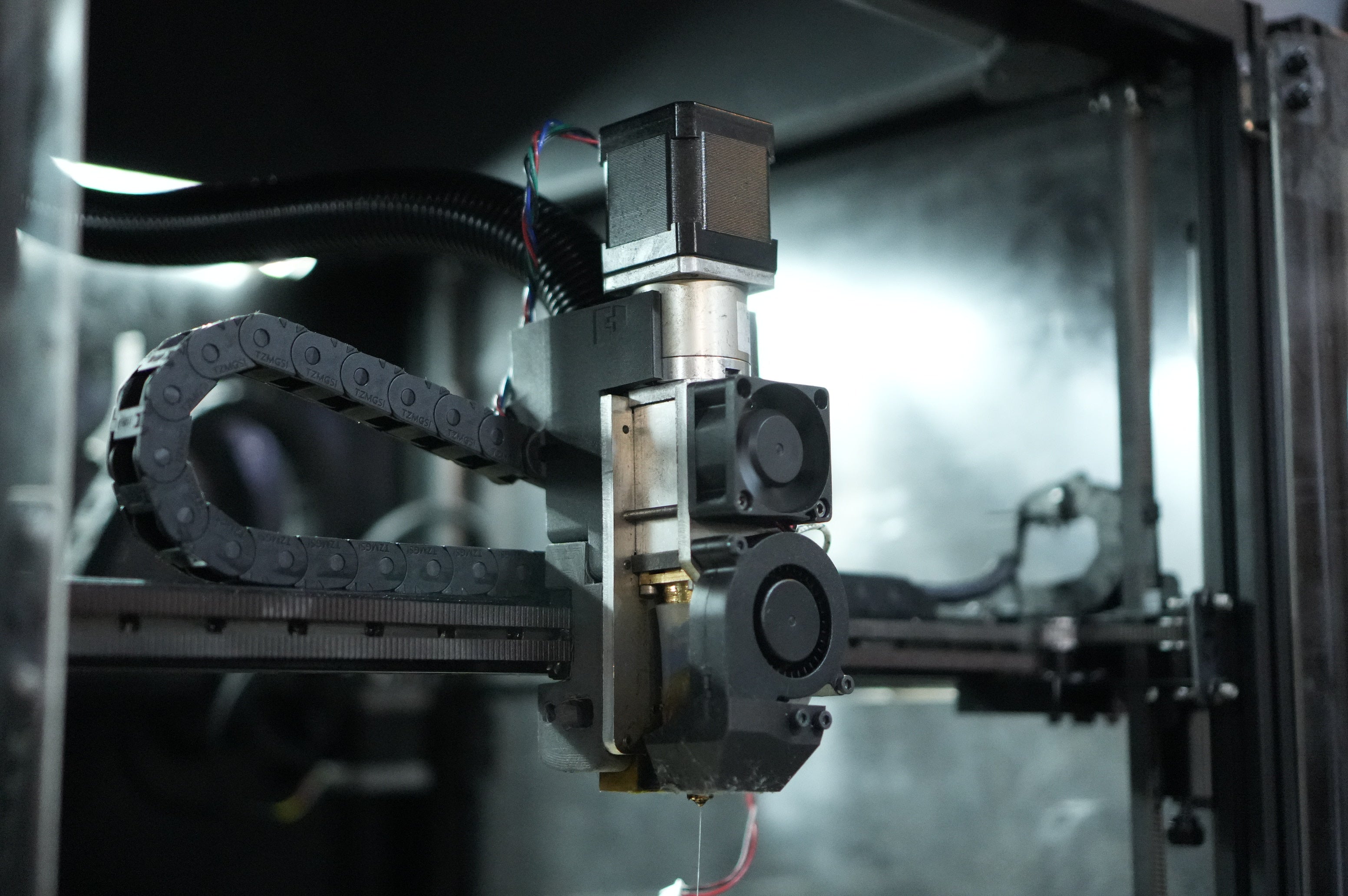

using our proprietary FGF additive manufacturing process.

We don't use filament. Our purpose built machines can process industrial grade polymers with no intermediate steps. This guarantees stronger, tougher, and better parts.

High-Performance Products for Any Ride

units in the field, and counting

5-Star Reviews

cycles to demonstrate their longevity

Latest Stories

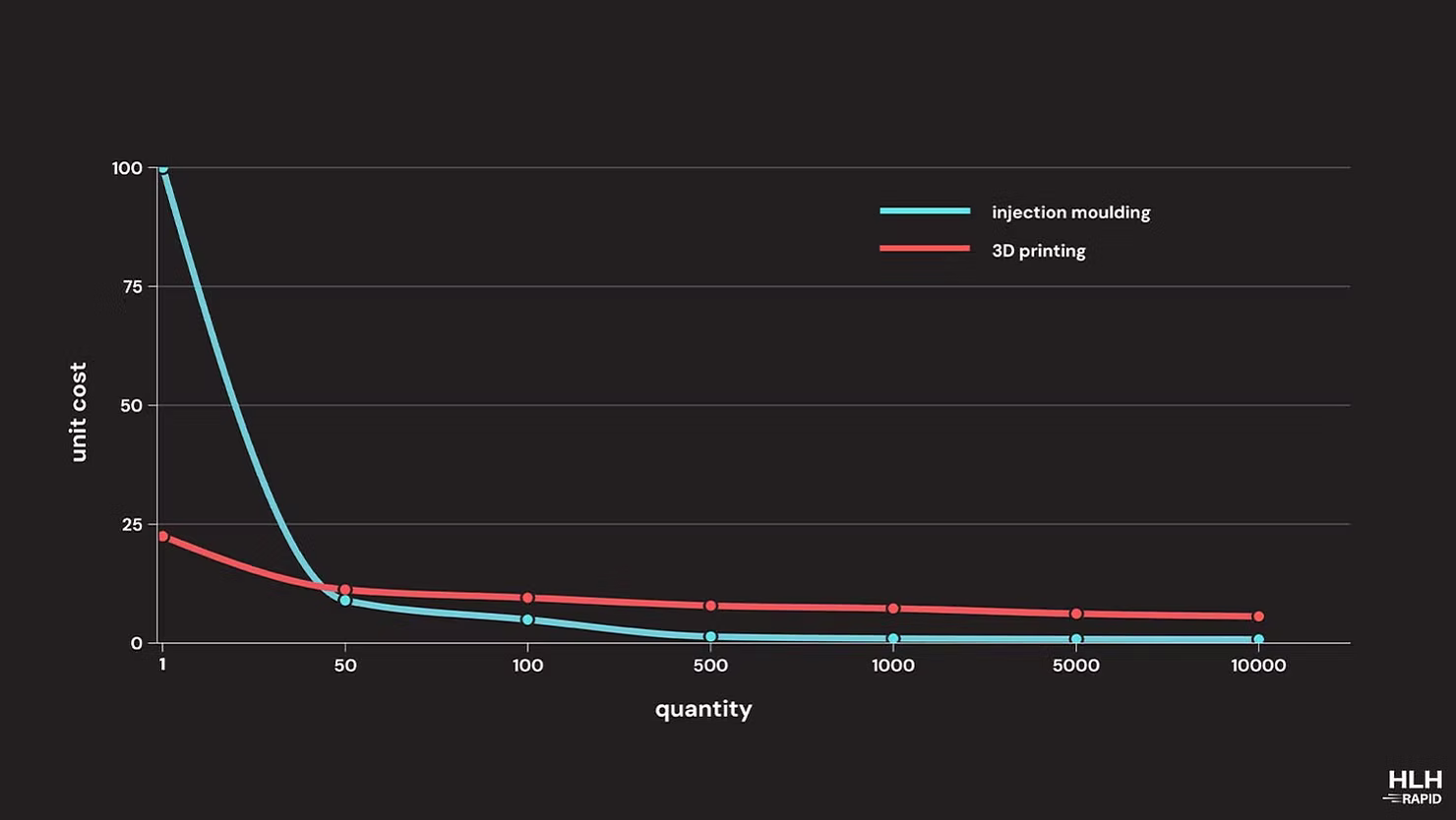

Why We Use 3D Printing (And Why It’s Not the Cheap Option Many Assume)

Reflecting on 2024: A Year of Growth, Innovation, and Community at Perry Parts

How Perry Parts Optimizes Stiffness with Density Modulation

To see the video version of this blog post: https://www.instagram.com/reel/DCXVawuSRhp/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==